Why silicone is the material of choice for most Rubber Keypads

A Comprehensive Guide to the Manufacturing and Handling of Rubber Keypads for Optimal Efficiency

The manufacturing and processing of rubber keypads play a necessary role in their performance and use. Material choice, style precision, and sophisticated production methods significantly affect their longevity and efficiency. Comprehending these elements is important for creating premium items. As different advancements emerge in this area, exploring their ramifications could disclose brand-new requirements for capability and user experience. What essential facets will shape the future of rubber keypads?

Understanding Rubber Keypads: Products and Types

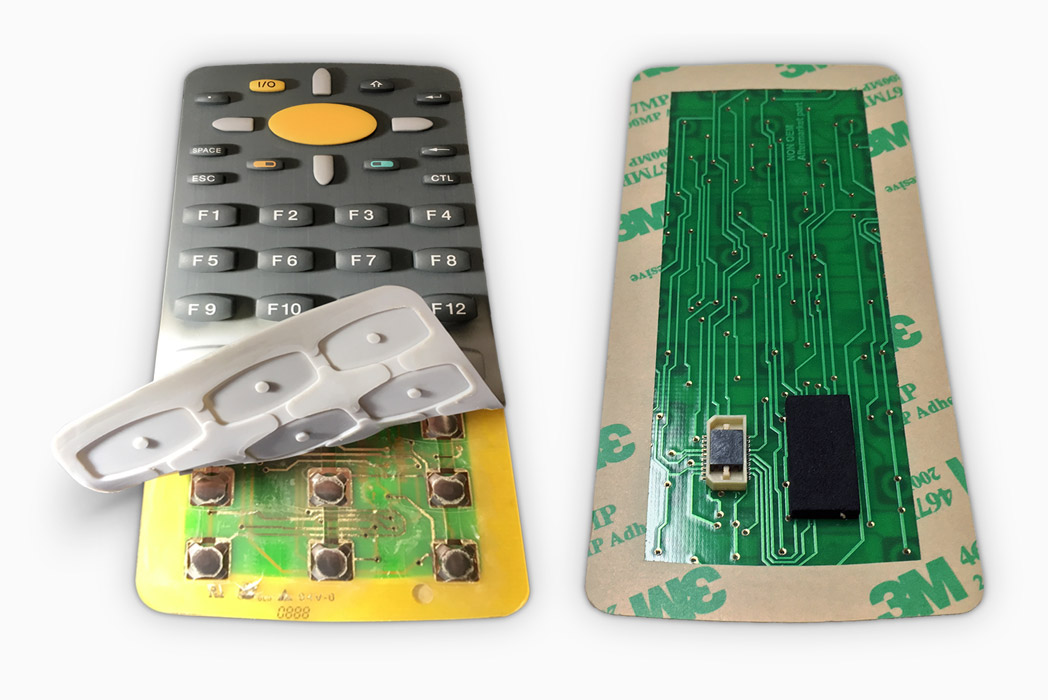

Rubber keypads are important parts in countless devices, using an equilibrium of durability and tactile responses. These keypads are primarily made from silicone or synthetic rubber, materials picked for their versatility and strength. Silicone rubber, specifically, is favored for its excellent temperature level resistance and longevity, making it perfect for various applications, from customer electronic devices to industrial equipment.

There are several types of rubber keypads, consisting of dome button keypads, which utilize a dome-shaped mechanism that offers tactile feedback when pressed. Furthermore, there are additionally flat keypads, which feature a smooth surface and are commonly made use of in medical gadgets and remote controls. The selection of product and kind affects the keypad's efficiency, really feel, and overall customer experience. Understanding these aspects is important for producers and designers intending to produce trustworthy and reliable interfaces in their items.

The Production Refine: From Layout to Manufacturing

The manufacturing procedure of rubber keypads entails a number of important phases, starting with layout and finishing with manufacturing. Originally, designers create detailed specifications and prototypes, ensuring the keypad fulfills visual and practical requirements. Computer-aided style (CAD) software program is commonly used to visualize the design and features before continuing.

Once the layout is wrapped up, product choice is important, with alternatives generally including silicone or all-natural rubber. In the following phase, molds are created based upon the approved layouts, which will form the keypads throughout production.

Following mold production, the production phase starts, where rubber is combined with additives to enhance performance. The mixture is then put right into mold and mildews and subjected to warm and stress, allowing it to strengthen and cure.

The ended up keypads undergo high quality checks to validate they meet recognized standards, complied with by product packaging for distribution. This comprehensive process assurances peak performance in the end product.

Secret Strategies in Rubber Molding

In the domain name of rubber keypads, numerous molding methods play a crucial role in figuring out the quality and capability of the end product. One widespread method is compression molding, where raw rubber is positioned in a heated mold and mildew and stress is used, allowing for effective mass production and uniformity. One more substantial strategy is shot molding, which entails injecting heated rubber right into a mold, using higher accuracy and facility forms. Transfer molding, a crossbreed of both methods, is also made use of, specifically for intricate designs, as it integrates the advantages of both processes. Additionally, fluid silicone rubber (LSR) molding is obtaining traction due to its adaptability and sturdiness, making it optimal for high-performance applications. Each technique possesses distinct attributes, affecting variables such as cycle time, product waste, and production costs. Choosing the proper molding method is necessary for attaining peak efficiency in rubber keypads.

Surface Area Finishing and Texturing Options

Surface finishing and texturing alternatives play a crucial duty in improving the responsive experience and visual allure of rubber keypads. Suppliers utilize various strategies to develop distinctive surface area attributes that impact customer communication and item layout. Typical ending up approaches consist of matte, shiny, and satin surfaces, each providing various visual effects and grasp levels. Texturing alternatives, such as raised patterns, grooves, or stippling, further improve capability by enhancing grip and reducing slippage during use.

Furthermore, particular textures can be tailored to satisfy ergonomic requirements, offering convenience throughout prolonged use. The choice of surface coatings and structures can be influenced by the designated application of the keypad, whether it be for customer electronic devices, vehicle controls, or industrial gadgets. Inevitably, careful factor to consider of these options contributes considerably to customer fulfillment and overall product performance, making them vital elements in the design and manufacturing procedure of rubber keypads.

Quality Assurance Actions in Rubber Keypad Manufacturing

Quality assurance steps in rubber keypad production are essential for making sure item integrity and performance. These measures incorporate material selection standards, extensive testing procedures, and rigid final assessment requirements. With each other, they create an extensive framework that assists makers support top quality throughout the manufacturing procedure.

Material Choice Criteria

Picking the appropriate products for rubber keypads is crucial, as it directly affects their durability, functionality, and customer experience. Key requirements for product choice include tensile stamina, resilience, and ecological resistance. The selection of rubber substance, such as silicone or polycarbonate elastomer (TPE), plays a crucial duty in accomplishing wanted tactile feedback and long life. Additionally, variables like chemical compatibility, temperature level stability, and UV resistance need to be taken into consideration to assure maximum efficiency in numerous applications. Makers ought to also evaluate the convenience of processing and cost-effectiveness of materials, stabilizing high quality with budget plan constraints. Ultimately, the best product option not only improves the keypad's efficiency yet likewise click now contributes to total item quality and consumer complete satisfaction.

Testing Treatments Implemented

After figuring out the ideal materials for rubber keypads, rigorous testing procedures are applied to confirm that the end products satisfy market requirements and client expectations. These procedures generally include mechanical screening, which reviews the resilience and elasticity of the rubber under different conditions. Furthermore, ecological screening evaluates the keypads' performance under temperature level changes, humidity, and direct exposure to chemicals. Electrical testing confirms the keypads operate properly with electronic components, validating responsiveness and conductivity. Furthermore, responsive responses is examined to ensure customer complete satisfaction. These comprehensive screening steps are necessary in recognizing any kind of inconsistencies or problems before automation, inevitably boosting the dependability and efficiency of rubber keypads in their desired applications.

Last Evaluation Standards

Complete last evaluation standards are crucial in rubber keypad manufacturing to guarantee that each system fulfills the defined criteria for capability and appearance. This process typically entails visual analyses to identify any type of surface area defects, find more such as staining or flaws. In addition, tactile assessments identify that the keypads respond precisely to touch, preserving the required level of sensitivity. Toughness examinations might also be carried out, imitating long term use to validate the durability of the keypad under numerous conditions. Moreover, adherence to market regulations and client requirements is validated to preserve top quality assurance. By applying these strenuous assessment actions, makers can greatly reduce the danger of issues, making certain that the last item is reliable and fulfills customer expectations, ultimately enhancing consumer complete satisfaction.

Innovations in Rubber Keypad Modern Technology

As technology continues to develop, developments in rubber keypad innovation are reshaping customer interfaces throughout numerous markets. One considerable advancement is the integration of capacitive touch sensors within rubber keypads, allowing for an extra receptive and flexible customer experience. This modern technology allows individuals to connect with devices via touch, improving performance without sacrificing the responsive responses that rubber keypads are known for.

Additionally, renovations in product formulations have caused the growth of even more durable, weather-resistant rubber, making keypads ideal for outside and industrial use. Enhanced printing strategies likewise permit high-resolution graphics and backlighting choices, raising presence and aesthetic appeal.

Innovations in manufacturing procedures, such as 3D printing, are enabling custom styles and quick prototyping, streamlining production timelines. These developments collectively contribute to much more user-friendly and efficient rubber keypads, guaranteeing they fulfill the needs of contemporary applications while preserving their core benefits.

Best Practices for Design and Functionality

Designing effective rubber keypads needs mindful evaluation of both aesthetics and functionality. Rubber Keypads. A well-designed keypad needs to balance ergonomic principles with aesthetic interest boost individual experience. Key variables consist of dimension, shape, and spacing of buttons, ensuring they are easy to press while protecting against unintended activation. Utilizing contrasting structures and colors can enhance exposure and tactile comments, helping users in distinguishing in between secrets

Additionally, the option of products plays a crucial duty; high-grade rubber substances can enhance resilience and resistance to use. It is likewise important to take into consideration the assimilation of functions such as backlighting and personalized graphics, which can boost functionality in various settings.

Ultimately, prototyping and customer screening are very useful in the layout process, permitting adjustments based on real-world responses. By adhering to these finest methods, producers can develop rubber keypads that not just look appealing however likewise meet the functional demands of individuals successfully.

Often Asked Questions

Just how Do I Select the Right Rubber Product for My Keypad?

To select the right rubber product for a keypad, one ought to take into consideration aspects such as resilience, environmental resistance, responsive responses, and compatibility with the intended application, making certain optimal performance and user contentment in different problems.

What Are the Environmental Effects of Rubber Keypad Production?

Rubber keypad manufacturing can result in environmental effects such as deforestation for natural rubber sources, pollution from chemical processes, and waste generation. Lasting methods and materials can minimize a few of these unfavorable results on communities.

Can Rubber Keypads Be Recycled or Recycled?

Rubber keypads can be reused, however the procedure depends on the certain products utilized in their manufacturing. Reusing them in different applications is additionally feasible, adding to throw away reduction and promoting sustainability in manufacturing methods.

What Is the Typical Lifespan of a Rubber Keypad?

The typical life-span of a rubber look at this now keypad normally varies from 5 to 10 years, relying on usage, environmental elements, and maintenance. Normal care can extend its functionality, while too much wear might shorten its durability.

Are There Any Type Of Health And Wellness Problems Associated With Rubber Keypad Materials?

There are possible wellness problems connected to rubber keypad materials, including allergies to particular chemicals and irritants made use of in manufacturing. Correct handling and recognition of product make-up can alleviate these dangers for individuals.

There are a number of kinds of rubber keypads, including dome switch keypads, which make use of a dome-shaped system that provides tactile responses when pushed. Selecting the suitable materials for rubber keypads is crucial, as it directly impacts their longevity, individual, and functionality experience - Rubber Keypads. After establishing the proper materials for rubber keypads, strenuous testing procedures are implemented to confirm that the last items satisfy industry criteria and customer expectations. Rubber keypad production can lead to ecological influences such as deforestation for all-natural rubber sources, contamination from chemical procedures, and waste generation. Rubber keypads can be recycled, however the process depends on the specific materials utilized in their manufacturing